Nidum Precision Tooling

Nidum Precision Tooling

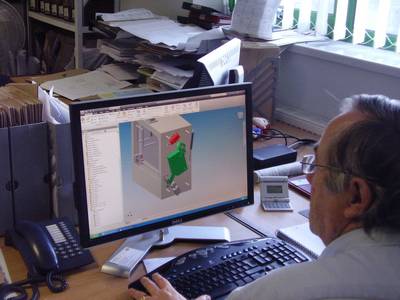

Established in 1962, Resolven based Nidum

Precision Tooling Ltd provides customised design and manufacturing

solutions primarily to blue chip manufacturers. The company came

under the ownership of Ewan and Julie McConnell in 2007 and their

vision was to broaden the customer base and create a centre of

engineering excellence in Neath Port Talbot.

Nidum creates customised engineering solutions

through the design and manufacture of custom built fixtures,

fittings, gauges and replacement parts. These enable

manufacturers with production line based processes to build and

introduce new products, enhance the performance of existing product

lines, or to obtain a cost effective source of spares and improved

parts. Customers include Tenneco Walker, Ford Motor Company, Senior

Automotive, Jaguar Landrover and BAE Systems.

Supported by Neath Port Talbot CBC,

the company invested in developing its premises with the

installation of a mezzanine floor. This enabled the relocation of

sister company Magor Designs Ltd, a recognised leader in the design

of gauging and jigs within the automotive and aerospace sectors, to

Resolven. Having both design and manufacturing capabilities on the

same site resulted in significant customer service benefits being

achieved. In addition to the design studio, offices, a meeting room

and a quality testing facility were created.

Nidum employs 24 and has a strong team of

highly skilled engineers and designers backed up by dedicated

administrative and finance functions. The company has a long

history of investing in its staff and currently employs 2

apprentices and will employ a further 2 by the end of 2011.

When further investment was required to

install a turnkey airflow, ventilation and temperature management

system to service the mezzanine facilities, business owner, Ewan

McConnell was referred to the South West Wales Local Investment

Fund.

“Needing to make a further investment in our

premises, we sought support from LIF. Ensuring consistent and

controllable air quality across the different activities was vital

to improving productivity, quality and achieving energy efficiency

gains.

The support through LIF has enabled us to move

more rapidly up the capability curve than if we had to fully fund

an incremental development ourselves. This means we can be more

competitive and offer additional products and services to both

existing customers and, potentially more importantly, sustain our

drive into new sectors and new customers. We have recently made

some significant in roads into new accounts – we have secured this

business on a mixture of expertise, service and facilities,” said

Ewan.

As part of its strategic development, Nidum

also invested in new equipment and wanted to establish a certified

co-ordinate measuring machine (CMM) capability within its Quality

Assurance facility.

“CMM machinery produces highly accurate and

universally accepted measurement and certification of machined

parts and assemblies with these products carrying a higher value

and level of customer confidence.

This investment had the potential to open

wider product sales opportunities for us within our existing

customer base, and the market sectors we were assessing all

required suppliers to possess CMM capability e.g. aerospace and

pharmaceutical.

This investment was a key component of our

strategy of broadening our customer base by breaking into new

market sectors. However, by this time, the economic downturn had

made raising finance difficult and without the further support of

the South West Wales LIF team, this investment would not have been

possible” said Mark Davies, newly promoted Managing Director of

Nidum Precision.

He added, “the installation of CMM technology

has given us a strong basis for self improvement and learning, as

we develop our overall quality assurance standards. Having this

facility in-house will greatly increase our capability to extend

our ISO9001 accreditation into relevant and recognised standards

for other sectors as we continue to broaden our customer base”.

The company has already seen significant

benefits from this investment with reduced lead times for customers

requiring CMM certification and an enhanced standing and

competitive position in its traditional markets and with new

sectors such as defence. The CMM machine has also proved to be a

great learning and training aid for the team in improving quality

standards.

Looking to the future Ewan added – “We have

benefited significantly as a business from support from both NPTCBC

and the LIF fund. Resources are precious for us all in the current

climate and we are gauging and digesting feedback from our recent

investments before we determine what we seek to do next. A key task

for the next few months is investment in staff training and

development to ensure the team have relevant skills and expertise

and have confidence deploying these with new and existing

customers.”

The investments made to date have provided the

company with the facilities needed to operate in an increasingly

competitive industry. Moving forward, Nidum will continue to invest

in new equipment that increases its technical capability, and to

produce high quality products that meet the demands of a wider

customer base representing a range of sectors.